Basic Info.

Model NO.

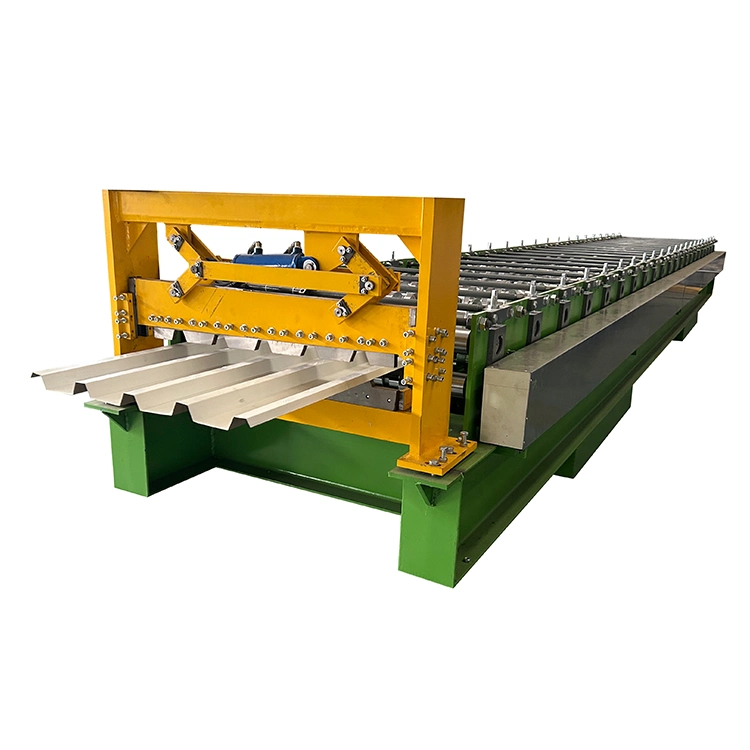

YX65-300-600

Customized

Customized

Usage

Standing Seam Roof Curving Machine

Dimension

1500mm/800mm/2000mm

Weight

1500kgs

Raw Material

Steel

Motor Power

4kw

Motor Power for Adjusted

0.75kw

Forming Steps

4

Thickness

0.6-1.0mm

Curving Speed

10-16m/Min

Min. Curved Radius for Aluminum

Convex Curved 2m, Concave Curved 6m

Transport Package

Standard Package for Export

Specification

SGS

Trademark

XHH

Origin

Xiamen, China

HS Code

84552290

Production Capacity

10-15sets/Month

Packaging & Delivery

Package Size

160.00cm * 90.00cm * 200.00cm

Package Gross Weight

1000.000kg

Product Description

Focus on roll forming machine for more than 19 years

Main Technic Data:

Curving Standing Seam Roof Panels to Convex Curved and Concave Curved, S-shaped and Wave-shape;

- Main Products -

- Company Profile -

| 1# Factory Lifetime Service | 2# CE Certificate |

3# Best Quality:select all best material for roller,shaft,cutter,PLC and driving system | |

4# Customized Profile:can design the profile according to customer request | |

Main Technic Data:

Curving Standing Seam Roof Panels to Convex Curved and Concave Curved, S-shaped and Wave-shape;

| Size | 1500*850*2000mm |

| Weight | 1500KGS |

| Motor Power | 4KW |

| Motor Power for Adjusting Models | 0.75KW |

| Forming Steps | 4 Steps |

| Curved Thickness for Aluminum | 0.6-1.0mm |

| Curved Thickness for Steel | 0.6-0.8mm |

| Working Speed | 10-16m/min |

| Curved Radius for Aluminum | Convex Curved 2m,Concave Curved 6m |

| Curved Radius for Steel | Convex Curved 4m,Concave Curved 8m |

Can not find the machine you need?

Why not customize it!

We have engineers with experience more than 17 years!

The configuration is not unique, we will provide you with customized services.

Why not customize it!

We have engineers with experience more than 17 years!

The configuration is not unique, we will provide you with customized services.

- Main Products -

- Company Profile -

XIAMEN XINHONGHUA MACHINERY CO. LTD.(FUJIAN XINHONGHUA MACHINERY CO. LTD) was founded in 2004.as the earlier company which engaged in the manufacture of cold roll forming machines,after the reform and innovation of more than 19 years,and on basis of manufacture of modern management concepts,strong technology,advanced production technology,perfect service system,we have been currently in the domestic leading position,and as good competitor among the same industry of world. Our company is located in the beautiful scenery,nice island of Xiamen.And have variety of products with stable performance,Always pay attention to improve the existing products and research and develop the new products.We have nearly 100 kinds of professional and technical personnel,with its strong ability of product design and development,to ensure a high level design of our product.For our products with light structure, reasonable design and updating styles,so we become well-know in the steel structure industry.And our products are mainly covered the railway station,city curtain wall,stadium,etc.field and have widely used in national key construction project. High quality products, good service to our products not only sell well all over China,and exported to Southeast Asia,Europe, Africa and Australia more than 40 countries and regions.